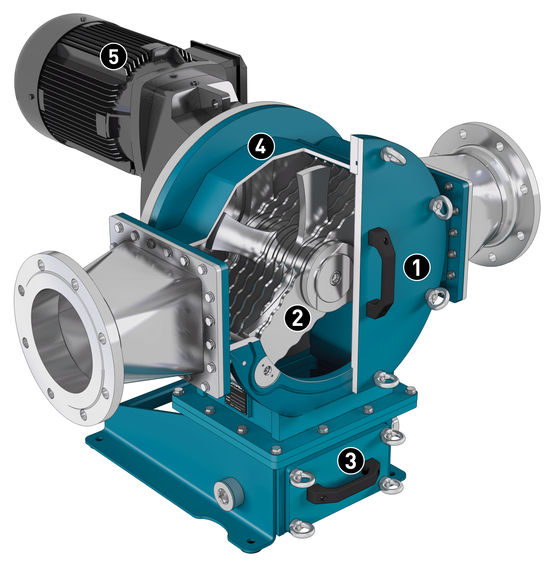

Multicrusher operating principle

The Multicrusher is the flagship product of the Börger macerating units’ series. It is designed to process a wide range of solid particles. Its robust design and powerful cutting mechanism make it suitable for use in wastewater management plants, industrial processes and similar applications. The machine uses a two-shaft system that ensures thorough crushing and solids separation.

The Multicrusher reliably chops coarse material such as fibers, wood pieces, plastics, membranes, textiles and many more and ensures that downstream machines and pumps operate smoothly. The cutting blades are made of hardened steel, which increases durability and extends the service life of the machine. In addition, the machine has a compact design, making it easy to integrate into existing systems, for example use together with mobile Börger pumps by mounting the pump and crusher on the same trailer.

The Multicrusher, like other Börger products, is characterized by its simple design, which ensures reliability, durability and easy maintenance.

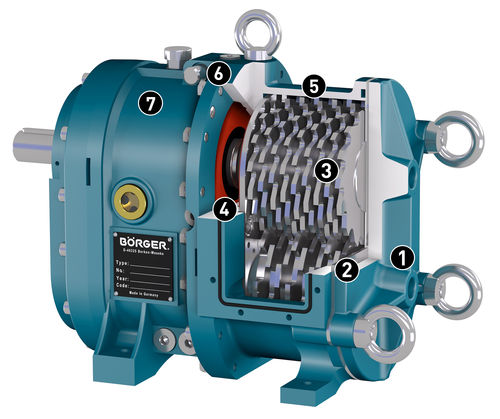

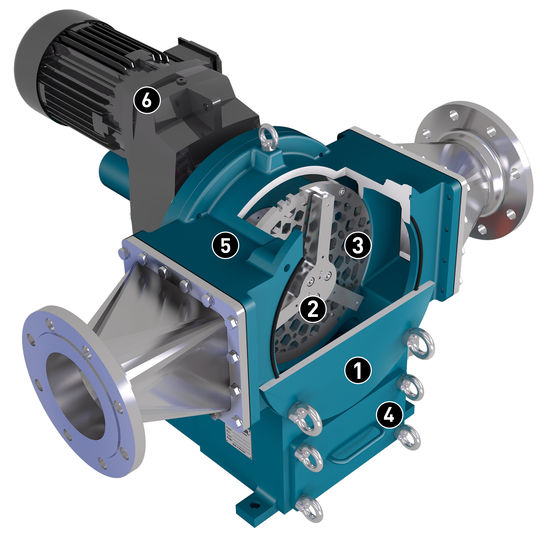

- Quick-release cover. Just unscrew 4 nuts (this can be done by hand, without any tools) and you already have access to the main parts of the Multichrusher located inside the crusher.

- Axial casing protection. The medium (that might be aggressive) flows through the interior of the casing and is fitted with an axial protective cover.

- Blades. The Multicrusher is designed so that you can choose which way the pumped medium flows by inserting the individual blade disks and defining the direction of rotation of the shafts. Various blade widths and cutting profiles determine the final cutting yield. The central fastening screws hold all the blade disks in position. Blades are one of the parts that wear out the most and require replacement, so it is important that such work is carried out by loosening just a few nuts, without any additional equipment.

- Shaft seals. Simply ideal. The space here allows the proven mechanical seal to be fitted without having to fully dismantle other components. No pipeline dismantling, no drive dismantling.

- Block casing. The casing is a single-piece block casing made of gray cast iron or stainless steel.

- Quench and control chamber. Added control and lubrication fluid have both a monitoring and lubricating function. Leakages in the upper overflow area indicate any unwanted seal defects in the upper overflow area. This ensures that contaminated liquid cannot penetrate the gear unit.

- Carrier and reducer gear. This is a very solid design. Extra large gears and bearings guarantee the overhung bearing system runs smoothly for a long time.