Börger has become a pioneer in the field of liquid pumping and handling technology, constantly pushing the boundaries of innovation. The separation technology devices it supplies – separators from the Bioselect RC and Bioselect BS product lines – demonstrate Börger’s commitment to providing efficient and versatile solids and liquid separation solutions.

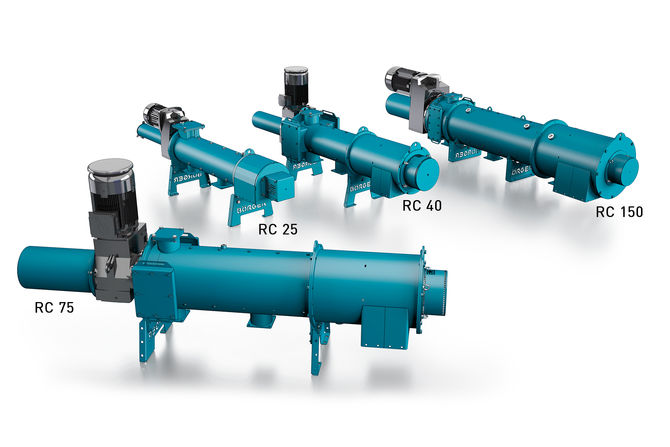

The Bioselect separators are available in 4 sizes, featuring maximum capacities of between 25 and 150 m³/h (110 and 660 gpm), the dry solids content is infinitely variable between 12 and 38 %.

The separators can be installed as stationary units for on-site operation, or as mobile separation stations mounted on a semi-trailer and capable of performing separation operations at different locations. The semi-trailer can also easily accommodate additional equipment that may be required for the separation operation, i.e. pumps, macerating units or even an electric generator, which helps achieve complete autonomy of the operation from environmental factors.